Why Do You Need a CMM Inspection?

Coordinate measuring machines, popularly referred to as CMM is used in the measurement of the physical geometrical attributes of a given object. Either of these machines can be run manually or automatically by an operator. A probe attached to the third moving axis on this machine helps define the device. Understand that CMM inspection help in the assembly and manufacturing process when testing certain parts against the intended design. When recording your X, Y or Z coordinates of a given object, narrow down to specific points which you can then have them analyzed using regression algorithm when constructing certain given features. All these points will be collected using a probe that’s manually positioned by operators or automatically done through Direct Computer Control, DCC. Both CMM and DCC can be programmed to measure certain identical parts.

Overview on CMM

The integration of CMM into the production process in labs or shop floors create significant differences in the quality of the final products. A problem arises when picking the right CMM for the task. If you make the wrong choice, you might end up picking the wrong machine, therefore adversely affecting your business strategy and performance eventually.

Benefits of CMM Inspection Services

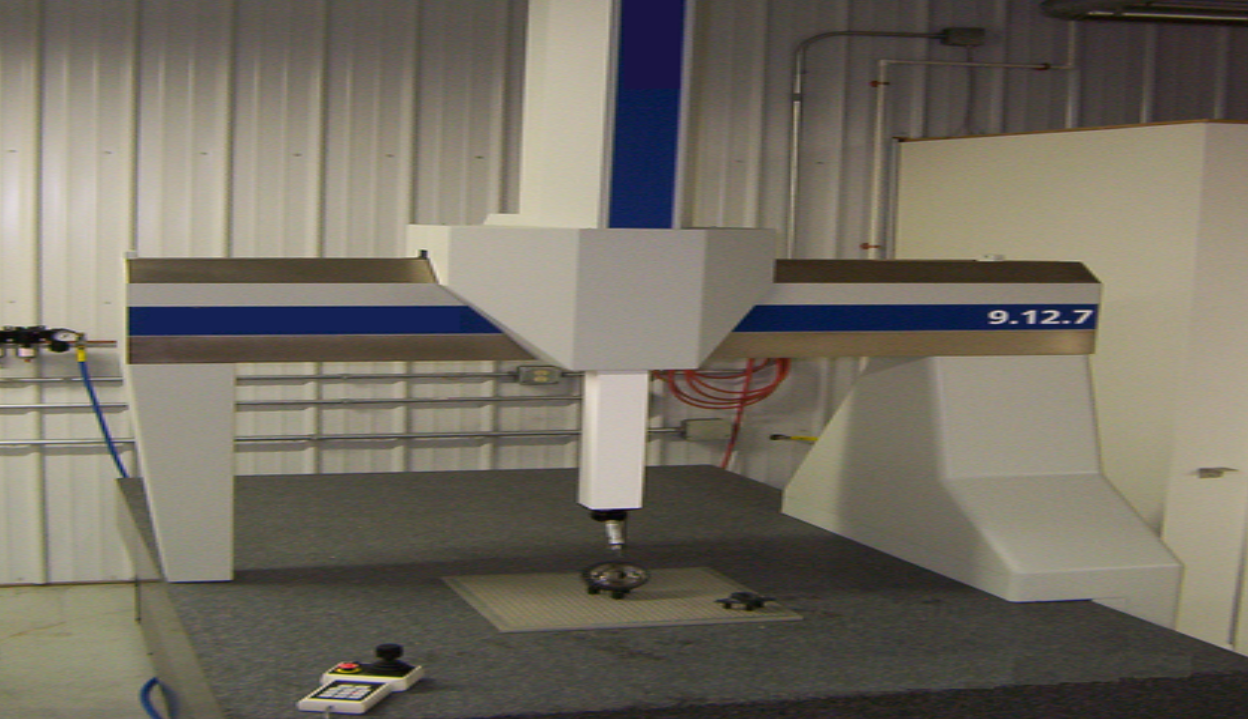

The CMM technology saves the users both time and money. As manufacturing gets more refined and complex, you are required to produce precise and accurate measurements. The use of CMM inspection services will provide favorable results for your company. You are at liberty to pick Gantry, Portable or Bridge CMM.

The CMM technology saves the users both time and money. As manufacturing gets more refined and complex, you are required to produce precise and accurate measurements. The use of CMM inspection services will provide favorable results for your company. You are at liberty to pick Gantry, Portable or Bridge CMM.

The days of using the dimensional lab approach or carving off large sections of the shop floors will be no more. You can also save floor space and utilize it in any given environment. Space is quite expensive in today’s business climate. Its quite difficult to measure off large components, so this will remain a challenge. In several cases, portable measuring machines will come to the rescue.

In the manufacturing, automotive, aerospace, and portable CMM sectors, you will notice CMM offers accuracy and convenience required to measure movable parts.

CMM services include the verification of quality, 3-dimensional inspections, certified tools, reverse engineering, CAD comparisons, and dimensional analysis. The quality of all services provided rank high on any company list.

What Are the Services Available?

CMM offers businesses a wide range of services that provide several benefits. To be precise, we are focusing on reverse engineering, design, assessment, test profiling, among others. Take time to enjoy inspections that would otherwise be hard to measure without the right instruments.

Conclusion

In the past decade, there has been a strong champion for the use of model-based definitions also referred to as DPD. More manufacturers are trading in their master parts for CAD models which carry a given level of tolerance that fosters compatibility with CAD and CMM software.

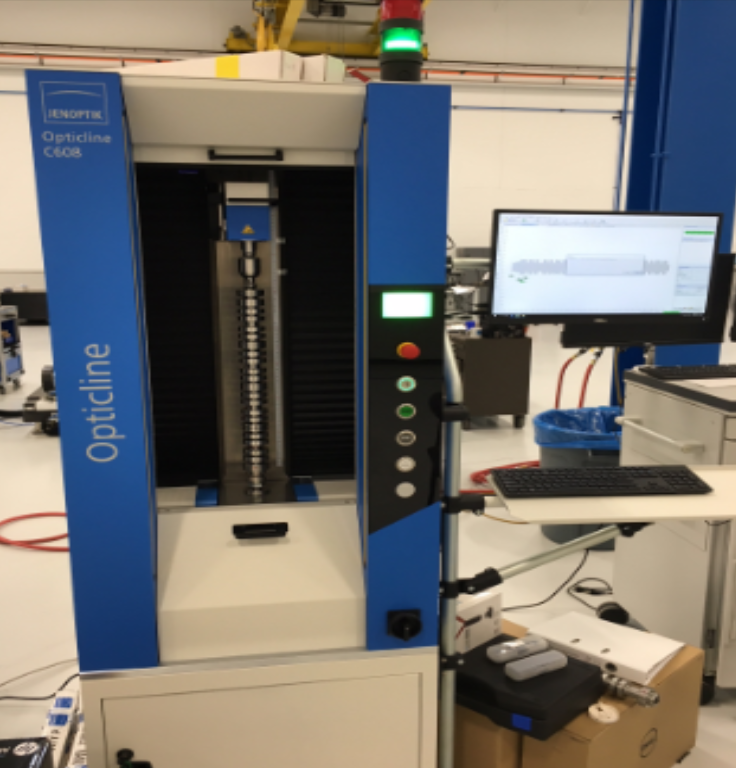

CMM software relies on traditional CAD models requiring users to rely on Unigraphics versus pro-engineers or Solidworks. The CMM software is heavily relied upon to read accurate data. A lot of factors need to be considered when including CMM types, software and the types of probes used.…